Design and Planning: Depending on the needs of the facility or building, the procedure usually starts with planning the electrical system's layout. This entails figuring out the kinds and dimensions of electrical equipment that are required, along with how the panels and foundation frames should be arranged to make room for them.

Material and Foundation: It's important to pick the right materials for the panels and foundation frames. Typical materials include steel, aluminum, and occasionally non-metallic materials like fiberglass, contingent on variables like corrosion resistance, load requirements, and climatic conditions.

Fabrication: The basic frames and panels are made by the specifications when the design is approved. To construct the necessary structures, may entail cutting, bending, welding, and assembling the metal components.

Installation: Depending on the design, installing the base frames entails either mounting them on walls or fastening them to the floor. The electrical equipment must be leveled and aligned carefully to guarantee stability and good operation.

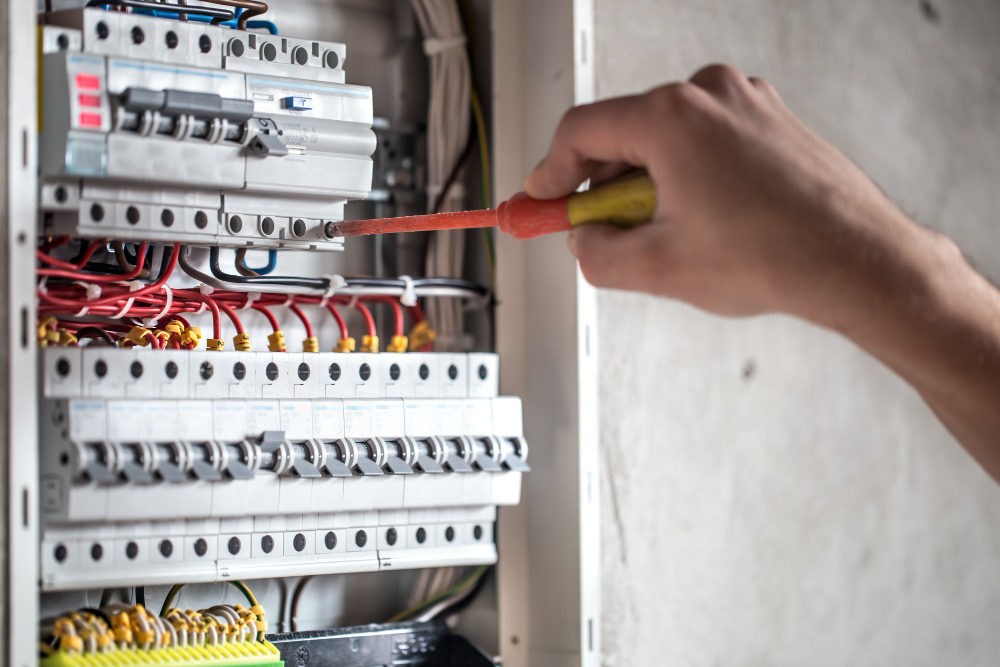

Panel Assembly: After that, the electrical panels are put together. These usually include internal cabling to link the equipment, a metal enclosure with doors for access, and mounting rails or backplanes for component installation.

Wiring and Connections: Following panel assembly, the schematic designs are used to guide the installation of the electrical wiring and connections. This entails directing signal, control, and power lines to the proper terminals inside the panels.

Testing and Commissioning: Following installation, the electrical system is put through testing to make sure every part is operating safely and correctly. To ensure correct functioning, this involves performing functional testing, continuity checks, and insulation resistance tests.

Documentation: Lastly, thorough documentation is created, which includes test results, equipment schedules, schematics, and drawings. Future maintenance, troubleshooting, and regulatory compliance all depend on this material.